Improve & Protect Laboratory Ventilation: Fume Hoods & Airflow Equipment

INTERNATIONALLY ACCREDITED

Internationally Accredited Ventilation Certification ANSI/ASHRAE, IEST, ISO & NSF-Compliant Lab Inspection Services in the US

Our laboratory testing and certification experts ensure your lab facility maintains or exceeds regulatory compliance. Compliant labs create a workplace that is both ecologically responsible and adheres to rigorous safety standards for your employees. Our NSF International accredited examiners primarily perform:

Lab Testing Quote

Annual Lab Recertification in the Midwest

Our laboratory testing and certification experts ensure your lab facility maintains or exceeds regulatory compliance. Compliant labs create a workplace that is both ecologically responsible and adheres to rigorous safety standards for your employees. Our NSF International accredited examiners primarily perform:

Primary Testing

- Air Velocity Evaluation – In-Flow and Down-Flow Velocity Patterns

- HEPA Filter Challenge Leak Test – PAO

- Visible Vapor Test – Air Flow Smoke Patterns

- Site installation assessment tests

Secondary Testing

- User Comfort Testing

- Sound Level Test

- Light Level Test

- Vibration Test

- Ultraviolet Light Level Test (where applicable)

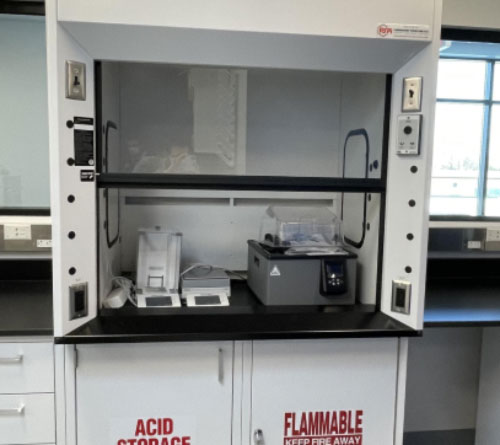

Chemical Fume Hood Certification

We recommend all new hood installations be tested on-site as mandated by the ANSI/AIHA/ASSE Z9.5-2012 Standard for laboratory ventilation. In addition to new types of fume hoods, we also recommend hoods which have never been performance tested undergo benchmarking to ensure optimal performance. PSA uses the ANSI/ASHRAE 110-2016 Test Method to evaluate chemical fume hood function. This test is recommended for commissioning a new hood, verifying the functionality of never-tested hoods, or when major mechanical changes are made to a hood or the lab in which the hood operates. ANSI/ASHRAE 110-2016 is a quantitative test using tracer gas to measure hood containment ability in parts per million (ppm). After testing, PSA will provide a comprehensive performance report for each fume hood. You can use this report to set a baseline whenever you need recertification. Following the initial ANSI/ASHRAE 110-2016 evaluation, a less rigorous test can be used for required annual evaluations. This comprehensive annual inspection ensures the hood is providing the same level of protection as found during the original inspection.Biological Safety Cabinet Inspections

To ensure proper function, biosafety cabinets must be certified at equipment installation and annually thereafter. The certification procedure as outlined by NSF International's Standard 49 ensures proper air balance and leak-free filters. PSA holds an NSF Accreditation for Class II Biosafety Cabinet Field Certification (certificate number C0106671-02).

Additional Testing & Certifications

- ANSI/ASHRAE: American National Standards Institute/American Society of Heating, Refrigerating and Air-Conditioning Engineers

- CETA: Controlled Environment Testing Association

- IEST: Institute of Environmental Sciences and Technology

- ISO: International Organization for Standardization

- NSF: National Science Foundation

Laminar Flow Hood Certification

Many labs use laminar flow to remove contaminated air from the room. Laminar flow benches, also known as Unidirectional Flow Clean Air Devices, are to be certified at installation and annually thereafter. PSA follows IEST-RP-CC002.3 and ISO14644-7 as the recognized standards. This certification ensures the laminar flow devices are operating at the correct airflow and the filters are sealed to provide particulate-free air to the work area. PSA's technicians have the latest factory-calibrated equipment and training.Clean Room Ventilation Standards Testing

Clean rooms are designed to be controlled areas of a lab free from contamination. Like all laboratory safety equipment, clean rooms must be commissioned at startup and validated annually thereafter. In addition to using regularly-calibrated testing equipment, PSA holds membership in the Controlled Environment Testing Association (CETA). PSA's thorough testing includes:- Airborne Particle Counting – ISO14644-1 (Federal Standard 209E optional)

- HEPA Filter Leak Test (where possible)

- Air Velocity/Volume Measurements (HEPA Filters)

- Calculating Air Exchange Rate/Hour

- Clean Room Pressurization Test

- Makeup Air Volume Test

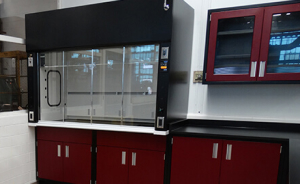

Fume Hood Options

Lab Ventilation Testing & Certification For Any Industry:

PSA Laboratory Furniture Works with Companies Across

the Country

PSA Laboratory Furniture provides laboratory furniture to companies across the United States. Our centralized geographic location allows efficient project coordination regardless of your company’s location. PSA’s goal is to respond to your laboratory's needs promptly nationwide.