How Professionals Ensure Smooth Fume Hood Installation

How Professionals Ensure Smooth Fume Hood Installation

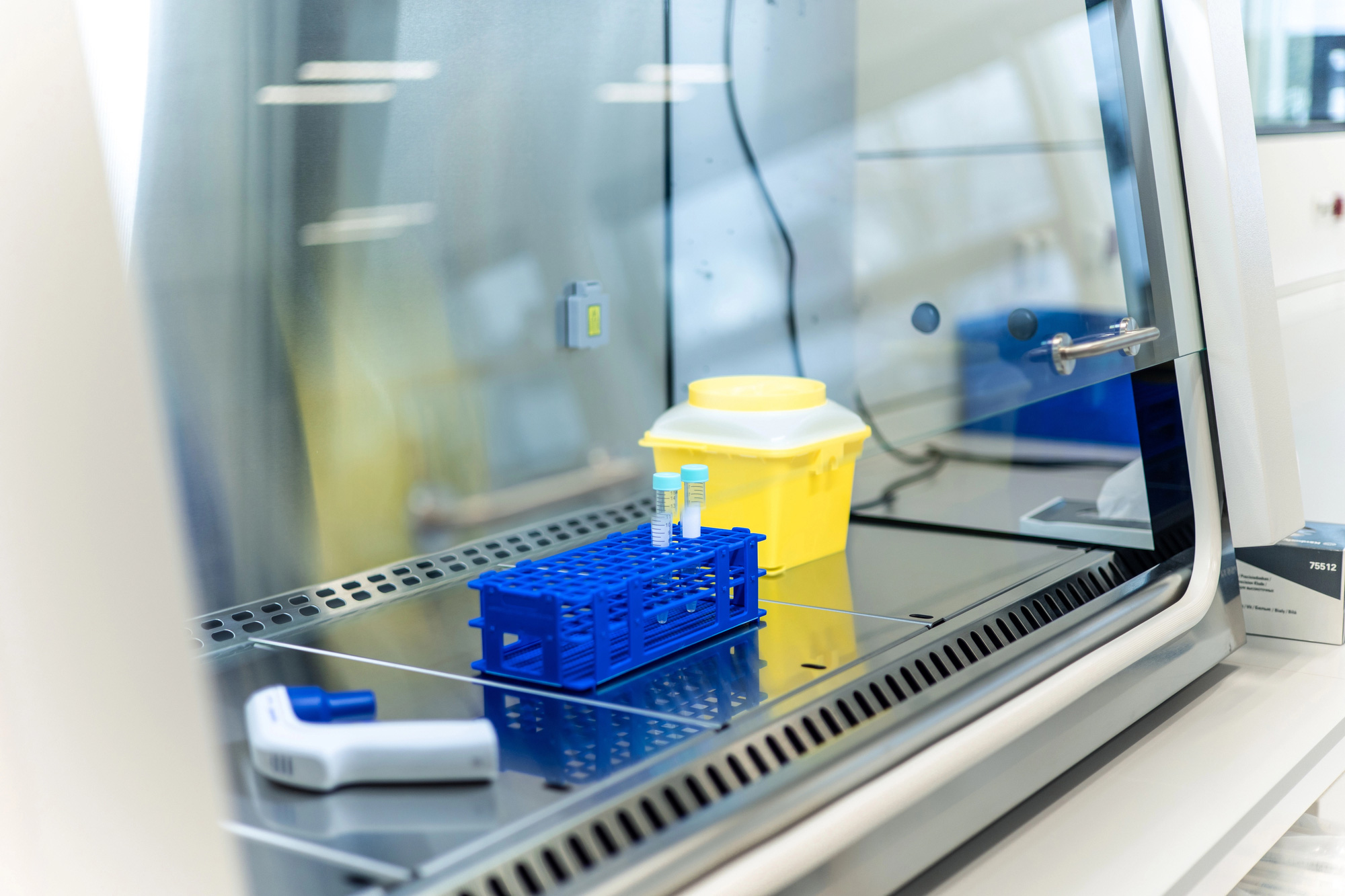

Installing a laboratory fume hood is more than just putting equipment into place. It’s a process that takes planning, precision, and the right expertise. A smooth fume hood installation helps maintain safety in the lab and keeps everything running the way it should.

Professionals follow a clear process to make sure that each hood is positioned and set up properly. From the first walkthrough to the final test, every part of the job has a purpose. Let’s take a closer look at what goes into a professional installation and what you should expect.

Planning Comes First

The process starts long before any tools come out. Professionals begin by visiting the site and checking that the space meets all the setup needs. That includes looking at power sources, ventilation access, plumbing lines, and general space around the hood.

They also make sure there’s no conflict with other lab equipment. Permits, local codes, and building regulations also come into play. All of that needs to be sorted out before installation day. Getting this step right saves time and avoids problems later on. A well-planned layout helps the installation team work faster and more efficiently.

Getting Ready with the Right Tools

Before any lifting or mounting happens, the crew checks that they have the tools they’ll need. Having the correct items, like a level, screwdrivers, and sealant, makes the job go faster and avoids delays. They also confirm that all parts of the fume hood are accounted for and that the hood itself is in good condition after shipping.

During this stage, ductwork connections and blower location are reviewed again. If anything has changed since the planning walkthrough, it’s easier to adjust now than during installation.

Setting the Foundation

The fume hood is always installed on a solid base. Professionals start by leveling the base cabinet. This step helps keep the hood stable, and it prevents long-term alignment problems. If needed, a support brace is added to help the epoxy work surface hold weight properly.

The work surface is then placed on top of the cabinet. Some installers seal it in place to stop any chemical spills from getting between the surface and the cabinet. The surface needs to sit flat and flush with the cabinet for a clean finish.

Unpacking and Assembly

Once the base is ready, the hood comes off the shipping skid. The team checks the packaging for damage and notes any missing pieces. After that, they remove the side panels and set aside the hardware that came with the hood.

Professionals follow the manufacturer’s instructions step by step. This includes checking the sash movement, installing baffles if needed, and making sure all moving parts work as expected. These early checks prevent trouble once the hood is installed.

Positioning the Fume Hood

Placing the hood onto the work surface is done carefully. The hood should never be lifted by the front airfoil or any fragile edge. Instead, the team uses the side rails or back frame to position it gently. The back of the hood is placed flush with the rear edge of the work surface, and the front overhang helps with proper airflow.

Once the fume hood is aligned, the back of the unit should be flush with the rear edge of the work surface. This allows for a stable and secure fit. The front overhang of the hood is designed to help secure proper airflow. It contributes to the overall effectiveness of the fume hood in protecting the user.

Finishing the Ventilation Setup

Ventilation is one of the most important parts of a working fume hood. The ductwork is connected based on the blower's location and airflow requirements. Installers confirm that the blower is the right size for the hood and that the duct runs are clean and clear.

Airflow gets tested with a handheld meter, and adjustments are made to reach the right face velocity. This test is repeated a few times to make sure the air is being pulled through the sash at the proper speed. If airflow is uneven or too low, it can impact how well the hood functions.

Wrapping Up the Installation

Once the hood is installed and hooked up, a few final touches bring the project to a close. The front panels are put back on, the sash is tested again, and all the fittings are tightened. Professionals also clean up the area, check labels, and document any final steps or notes. That includes the hood’s serial number, installation date, and airflow test results.

Training the Lab Team

Before the job is fully complete, the lab staff should be trained on how to use the new fume hood. Professionals explain how to operate the sash, how to avoid blocking airflow, and how to keep the hood clean and safe.

Simple tips like where to place items inside the hood and when to close the sash can make a big difference in performance. Training often includes basic troubleshooting, too. For example, staff should know what to do if the airflow monitor gives an alert or if the sash doesn’t slide properly. This way, small issues can be caught before they turn into big ones.

At PSA Laboratory Furniture, we’ve been working with labs across industries since 1983. We build high-quality, American-made lab furniture, fume hoods, and custom solutions that fit your space and workflow.

Our project management process keeps things organized and on track. We start with a consultation, help you through the design and revisions, and then move through quoting, ordering, and delivery. If you choose our non-mechanical installation option, we will work closely with you to coordinate the delivery of materials and schedule the date our installers will be on-site to complete the installation.

If you're planning a new lab space or upgrading old equipment, let’s work together. PSA Laboratory Furniture is ready to help make your next project as smooth as possible from design through delivery.

Talk to our team here and let’s get your lab moving in the right direction.